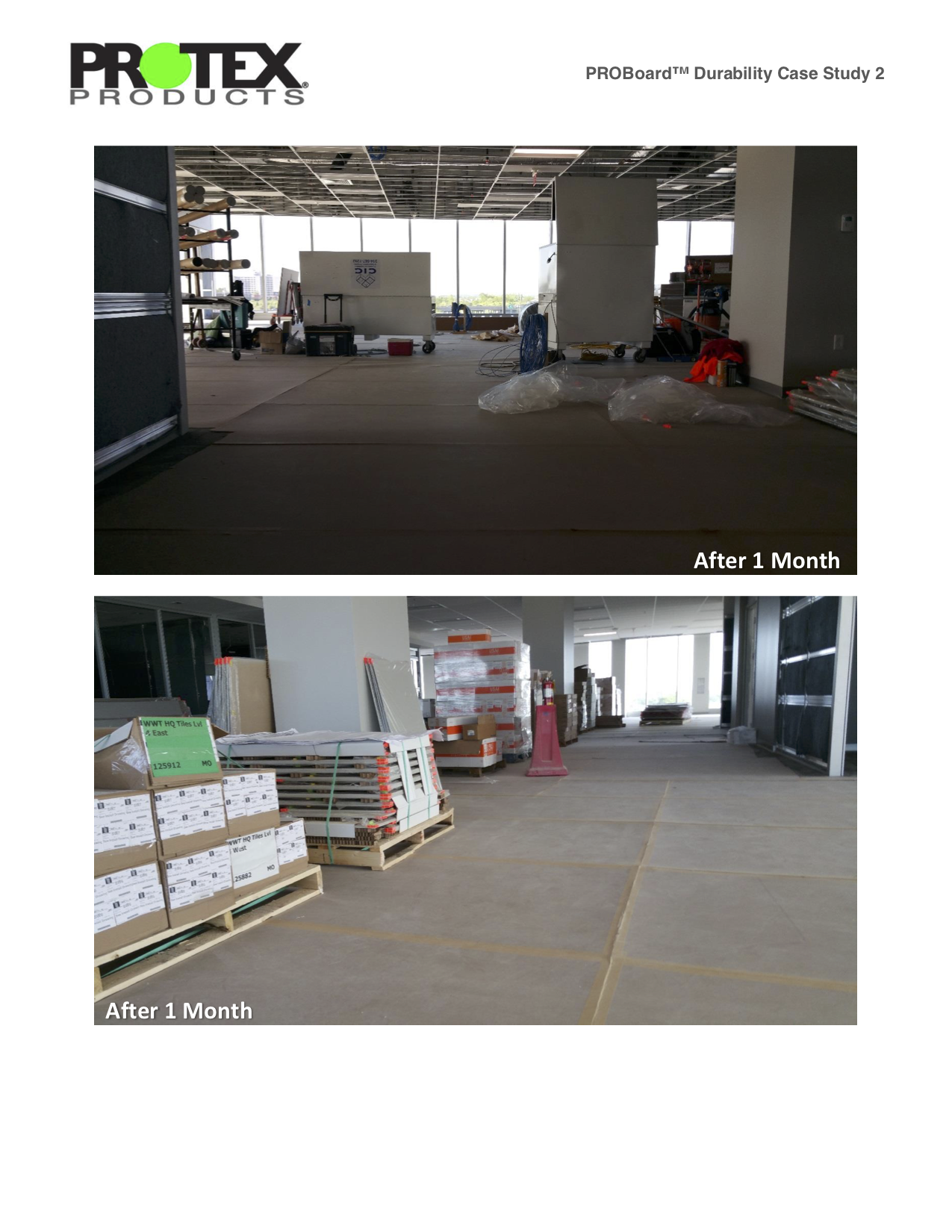

PROBoard Durability Case Studies

Whatever your temporary job-site surface protection needs – PROTEX® has you covered.

PROTEX® offers a complete lineup of patented temporary surface protection solutions specifically designed and field-tested for your job site needs.

““PROBoard worked great. It was super strong and saved us a lot of time and money. I am absolutely pleased with the product and will definitely be using PROTEX again.””

Download our PROBoard Durability Case Studies

Durability Case Study #1

Project Description: New construction of 13 story residential building in Chicago, IL

Project Budget: $75,000,000

Products Utilized: 230,400 sf of PROBoard™ 24 and 768 Rolls of KTape™

Floor Surface: Polished and Sealed Concrete

Project Length: 6 Months

PROBoard™ 24’s Tru-Lay Flat™ sheets made moving and installation much easier and faster.

Using the GaffGun™ made installing the 26.2 miles of KTape™ seam tape extremely easy and fast

After 1 week of use and moving tens of thousands of pounds of drywall and other building materials into position there is no delamination, curling, penetrations or KTape™ seam tape breakage.

After 2 months of use, the PROBoard™ is covered in dirt, drywall mud and equipment but there is no curling, penetrations, delamination or KTape™ seam tape breakage. The PROEdge™ shows several impact scuff marks but no penetrations

After 3 months of use, there is significant debris, drywall mud, impact scuffs and even thick piles of paint over the PROBoard™ but there is no delamination, curling, penetrations or KTape™ seam tape breakage.

After 6 months of use, it may not look pretty because of all the debris, water stains, drywall mud, paint and impact scuffs covering almost every inch of the PROBoard™ but there were no stains or other damages to the floor beneath.

There is some minor delamination and heavy scuffing of the PROBoard™ as well as some minor KTape™ seam tape breakage but that is to be expected after protecting the job-site surfaces from the 1,000+ different construction trade personnel, the constant repositioning of construction equipment and building materials and the myriad of construction phases over a 6-month period.